Commercial UV Systems

£550.00 – £4,100.00

Our Commercial UV Systems are designed to treat biologically unsafe water from private water supplies and for water that has been treated to remove biocides or stored for a period of time. Passing water through the stainless steel reactor chamber and exposing it to UV-C rays destroys the DNA of bacteria and microbes, sterilising the water in the process. Our range of Commercial UV Systems are manufactured in the EU by Sita UV and are WRAS approved, ensuring they are safe for use with drinking water. With a 304 stainless steel reactor chamber and separate control panel featuring an LCD display with operation indicator light, hours run timer and free alarm relay contact.

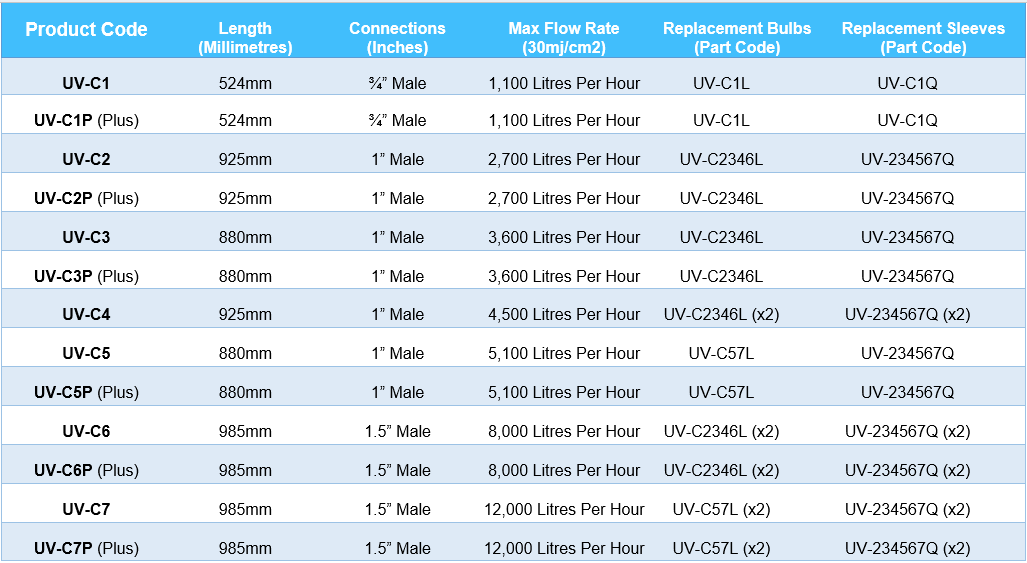

We offer a range of system sizes to suit flow rates between 1,100 and 12,000 Litres per hour, with the ‘plus’ option offering additional intensity meter, temperature meter and high temperature automated shut down.

Why Choose Our Commercial UV Systems?

- WRAS approved system for safe drinking water

- High flow rates up to 12,000 Litres per hour

- Control panel with indicators of operation

- ‘Plus’ version with additional features

Need help with our Commercial UV Systems? Give us a call on 01622 933 853

Description

UV systems are commonly found on farms, in factories and on sites with a private water supply. They are popular because of their effectiveness in treating bacteria without adding anything to the water, such as harsh chemicals like chlorine.

The Sita UV range delivers high UV dosage rates of 30mj/cm² well above the minimum requirement of 16mj/cm². The UV bulbs have an estimated lifespan of 9,000 working hours (375 days) and the systems feature an ‘hours run’ indicator as standard, so you know how long the bulb has been in service. All systems have a remote on/off contact, resettable hour timer, lamp function control, alarm LED with the ‘plus’ models also offering reactor temperature and irradiance meter with alarm and automatic high temperature shut off.

It is important to ensure water is particulate free before entering your UV system. It is best practice to filter down to 5 micron before UV treatment to prevent shadowing of the UV light. Shadowing is caused when particulate passes through the chamber, giving bacteria somewhere to hide from the UV light and can lead to improper treatment of your water.

How Often Do I Need To Replace The Bulb In These Commercial UV Systems?

UV bulbs should be replaced annually. It is also recommended to clean and inspect the quartz sleeve every 3-6 months and replace if damaged.

Key Product Information

- Treats water without the need for harsh chemicals

- Long life bulbs operate for up to 9,000 hours

- High UV dosage rate of 30mj/cm²

- Easy to install and maintain

- Low energy consumption

Compatible Products

Need help with our Commercial UV Systems? Give us a call on 01622 933 853

Specification

| Suitable For | Food & Beverage, Farms, Private Water Supplies, Boreholes, Factories, Commercial, Industrial, Cosmetics, Manufacturing, Light Commercial |

|---|---|

| Material | 304 Stainless Steel (316L Stainless Steel Available Upon Request) |

| Connections | Please Refer To 'Comparison Table' Tab |

| Max Flow Rate | Please Refer To 'Comparison Table' Tab |

| Length | Please Refer To 'Comparison Table' Tab |

| Max Pressure | 9 Bar |

| Air Temperature | 2-40°C |

| Control Panel Dimensions | 215mm x 215mm x 90mm |

| Power Supply | 230V-50/60 Hz (IP 55 Protection) |

| Lamp Power | 40W |

Comparison Table